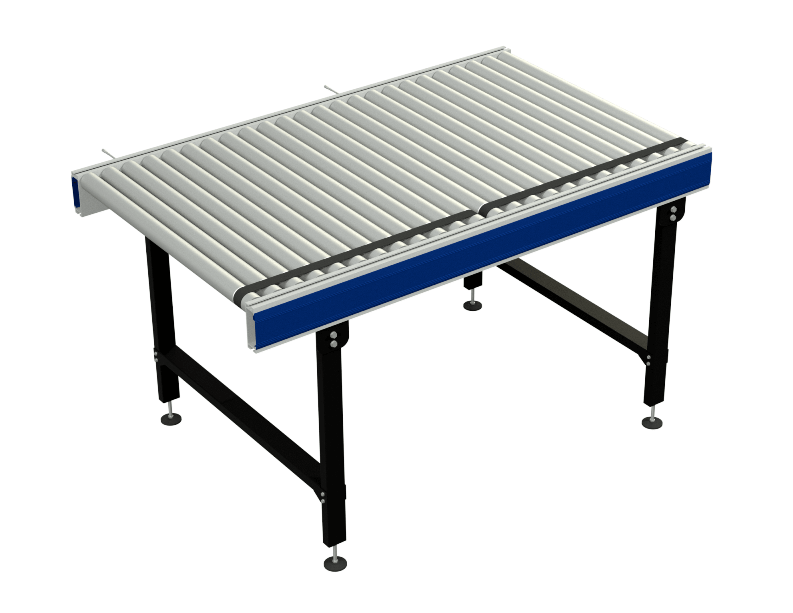

24V Roller Conveyor

This conveyor serves as a transport conveyor of unit loads with the help of a E-qube Ai drive controller. Each section is powered by a drive roller that is connected to a fixed number of slave rollers via round belts. 1 e-qube can control 1 drive roller. PVC side cover caps both sides included. Frame built up out of anodised extrusion aluminium profiles.

| General Data | |

|---|---|

| Conveyor speed | 0,05 – 1,38 m/s |

| Max. load capacity | 50 kg (Maximum load capacity is depending on the combination of speed & load) |

| Ambient temperature | 0° to 40°C |

| Ambient humidity | Less than or equal to 90% (no condensation) |

| Noise level | < 70 dB (Noise level can vary due to surrounding conditions) |

| Frame | Aluminium extrusion profile |

When it comes to material handling, efficiency is key. That’s why 24V roller conveyors have become increasingly popular in various industries, from automotive and electronics to pharmaceuticals and food processing. In this article, we’ll explore the benefits of 24V roller conveyors and why they’re the go-to solution for many businesses.

What are 24V Roller Conveyors?

24V roller conveyors are powered by 24-volt DC motors and are commonly used for light to medium-duty applications. They consist of a series of rollers placed at specific intervals, allowing materials or goods to move freely. The rollers are driven by a series of belts or chains, providing power to move the goods from one point to another.

Benefits of 24V Roller Conveyors:

- Energy Efficiency:

Compared to traditional powered conveyors, 24V roller conveyors consume less energy. This is because they use only the necessary amount of power to transport goods, reducing overall energy costs. - Quiet and Smooth Operation:

24V roller conveyors operate quietly, providing a comfortable and safe work environment for employees. The smooth operation also reduces the risk of product damage during transportation. - Customizable:

24V roller conveyors can be customized to fit specific business needs, such as size, speed, and load capacity. This ensures that businesses get the most out of their investment while meeting their unique material handling requirements. - Safe and Easy to Use:

With low voltage and a compact design, 24V roller conveyors are safe and easy to use. They require minimal maintenance and can be quickly and easily installed, reducing downtime and increasing productivity. - Space Saving:

The compact design of 24V roller conveyors allows businesses to save valuable floor space. This is especially beneficial for businesses with limited space, allowing them to maximize their facility’s potential. - Cost Effective:

24V roller conveyors are cost-effective, making them an ideal solution for businesses looking to improve their material handling efficiency without breaking the bank. They offer a great return on investment by increasing productivity, reducing labor costs, and minimizing material damage.

24V roller conveyors are an excellent solution for businesses looking to improve their material handling efficiency. They are energy-efficient, quiet, customizable, safe, and easy to use, making them an ideal solution for various industries. By investing in 24V roller conveyors, businesses can reduce downtime, increase productivity, and ultimately boost their bottom line. Contact us to get a quotation for your project.

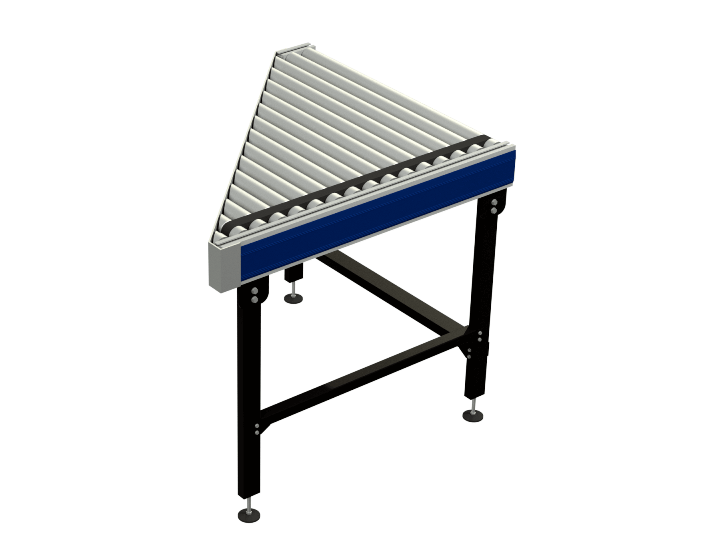

Product Images

Get A Quote Today

Talk to us about your project, we can assist you with advice and know-how from our decades of experience.