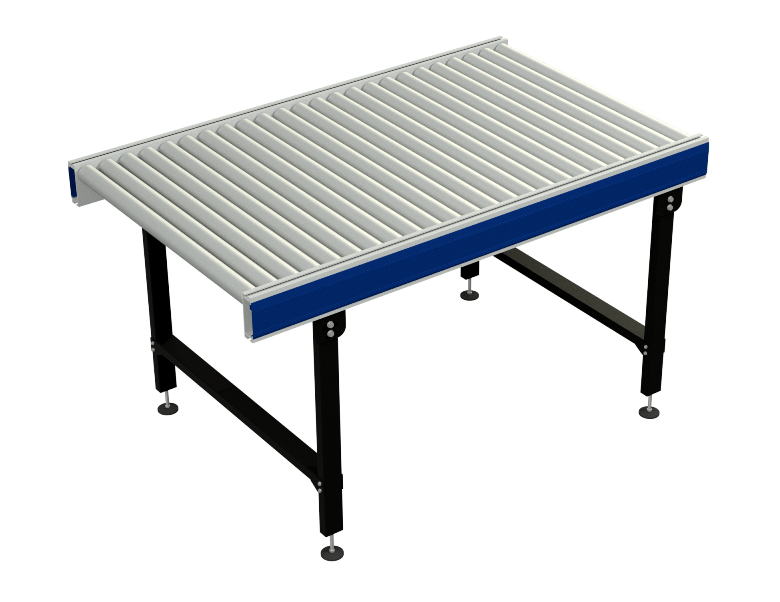

Non-powered Roller Conveyor

This conveyor transports materials either manually or via gravity down a slope and is often used as an assembly and picking line. PVC side cover caps both sides are included. The frame built up out of anodised extrusion aluminium profiles.

| General Data | |

|---|---|

| Max. load capacity | 50 kg |

| Ambient temperature | 0° to 40°C |

| Conveyor width | 420, 620 and 820mm |

| Frame | Aluminium extrusion profile |

Efficient Material Handling with Non-Powered Roller Conveyors

Material handling plays a vital role in the smooth operation of industries such as manufacturing, warehousing, and distribution. When it comes to optimizing material flow without relying on electrical power, non-powered roller conveyors are the go-to solution. In this article, we’ll explore the benefits and versatility of non-powered roller conveyors and how they can enhance your material handling processes.

Understanding Non-Powered Roller Conveyors

Non-powered roller conveyors, also known as gravity roller conveyors, rely on the force of gravity to move materials or goods along a series of rollers. These conveyors are ideal for transporting lightweight to medium-weight items, such as cartons, totes, and packages. The incline of the conveyor and the weight of the load determine the speed at which the items move.

Advantages of Non-Powered Roller Conveyors

- Cost-Effective Solution:

Non-powered roller conveyors are a cost-effective option as they do not require electrical power to operate. This eliminates the need for motors, controls, and power consumption, resulting in lower operational costs for businesses. - Simple and Low Maintenance:

With a minimal number of moving parts, non-powered roller conveyors are easy to install and maintain. They have fewer components that can wear out or malfunction, reducing the need for frequent repairs. This simplicity translates to less downtime and improved productivity. - Versatility and Flexibility:

Non-powered roller conveyors are highly versatile and adaptable to various material handling applications. They can be customized and configured to fit different layouts, allowing businesses to optimize space and create efficient workflows. Additionally, these conveyors can be easily integrated with other conveyor systems for seamless material flow. - Enhanced Ergonomics and Safety:

One of the key benefits of non-powered roller conveyors is improved ergonomics. By utilizing gravity, these conveyors minimize the need for manual pushing or pulling, reducing the risk of strain-related injuries for workers. Moreover, non-powered roller conveyors are generally considered safe as they operate at a controlled speed and offer excellent visibility of the transported items. - Eco-Friendly Solution:

In today’s environmentally conscious world, non-powered roller conveyors provide an eco-friendly material handling alternative. By harnessing gravity, they contribute to energy conservation and reduce carbon emissions. Choosing non-powered roller conveyors aligns with sustainable business practices.

Non-powered roller conveyors offer numerous advantages for businesses seeking an efficient and cost-effective material handling solution. With their simplicity, low maintenance requirements, and versatility, these conveyors can streamline workflows, improve ergonomics, and contribute to a greener environment.

Incorporating non-powered roller conveyors into your operations can lead to increased productivity and enhanced overall efficiency.

Get A Quote Today

Talk to us about your project, we can assist you with advice and know-how from our decades of experience.