Conveyors are an essential component in various industries, such as manufacturing, packaging, and mining, where materials and goods need to be transported from one place to another. The use of conveyors helps to improve productivity, efficiency, and safety in the workplace. However, with various conveyor types available, it can be challenging to determine the best one for your business needs. In this article, we’ll explore different conveyor types and their benefits.

-

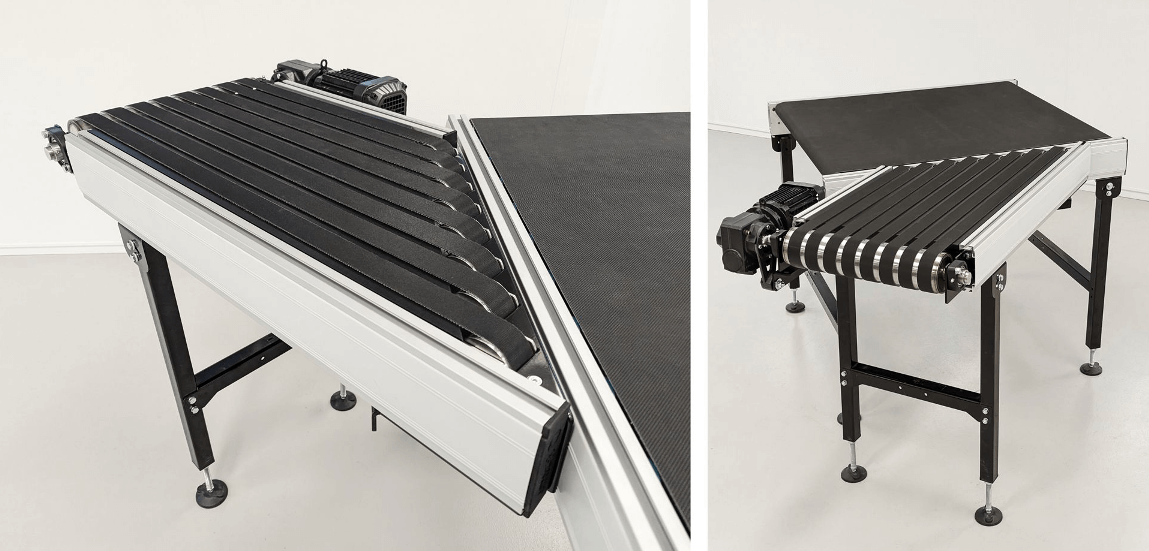

Belt Conveyors Belt conveyors are the most commonly used conveyor type in many industries. They consist of a belt that rotates around two or more pulleys, transporting materials or goods from one point to another. Belt conveyors are versatile, easy to install, and require minimal maintenance. They can handle various materials, including bulk materials, boxes, and packages.

-

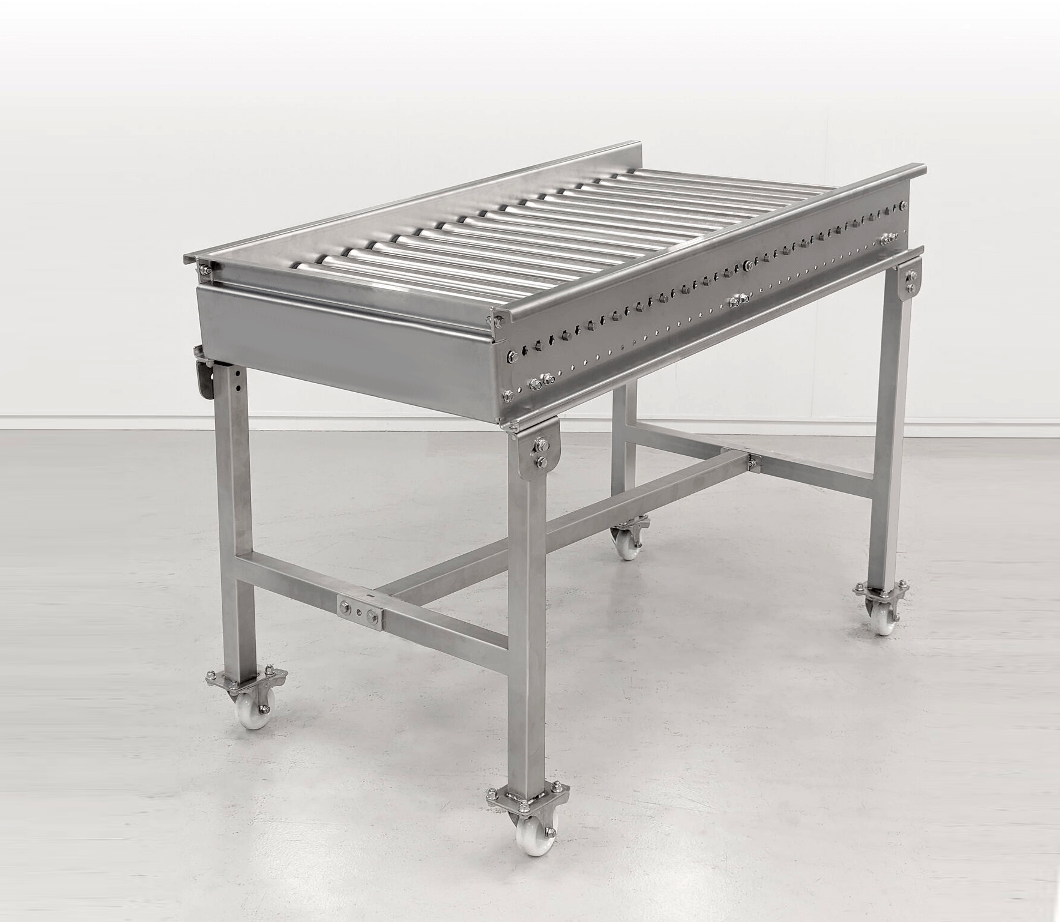

Roller Conveyors Roller conveyors consist of a series of rollers placed at specific intervals, allowing materials or goods to move freely. They are commonly used in manufacturing and distribution centers to move boxes and packages. Roller conveyors are easy to install, maintain, and can handle heavy loads.

-

Screw Conveyors Screw conveyors are a type of conveyor that uses a rotating screw to transport materials or goods from one point to another. They are commonly used to move bulk materials such as grains, chemicals, and powders. Screw conveyors are easy to install, low maintenance, and can handle a wide range of materials.

-

Chain Conveyors Chain conveyors consist of a chain that runs along two or more sprockets, transporting materials or goods. They are commonly used in automotive, mining, and construction industries to transport heavy loads. Chain conveyors are durable, require minimal maintenance, and can handle heavy loads.

-

Pneumatic Conveyors Pneumatic conveyors use air pressure to transport materials or goods from one point to another. They are commonly used in the food, chemical, and pharmaceutical industries. Pneumatic conveyors are ideal for transporting delicate materials that require gentle handling.

-

Bucket Conveyors Bucket conveyors consist of a series of buckets attached to a chain or belt, transporting materials or goods vertically or horizontally. They are commonly used in the mining and agriculture industries to transport bulk materials. Bucket conveyors are durable, low maintenance, and can handle heavy loads.

In conclusion, selecting the right conveyor type for your business needs is crucial to improve productivity, efficiency, and safety in the workplace. By understanding different conveyor types and their benefits, you can make an informed decision that aligns with your business needs. Remember to consider factors such as the type of material or goods to be transported, the distance, and the required speed to select the best conveyor type.

Talk to our expert team about your conveyor requirements.